Understanding the science behind epoxy coatings and how they perform in this environment is important for anyone considering concrete coatings for their home or business. We’ll break down some important terms below, helping you understand the epoxy flooring world.

Epoxy Flooring World: Coating Types

Understanding the primary types of coatings is essential for choosing the right coating system for your Colorado Springs project. However, each coating type comes with it’s benefits and disadvantages. It is important to keep in mind that a “coating system” consists of multiple layers of these coating types…and different coating types can be used within the same system!

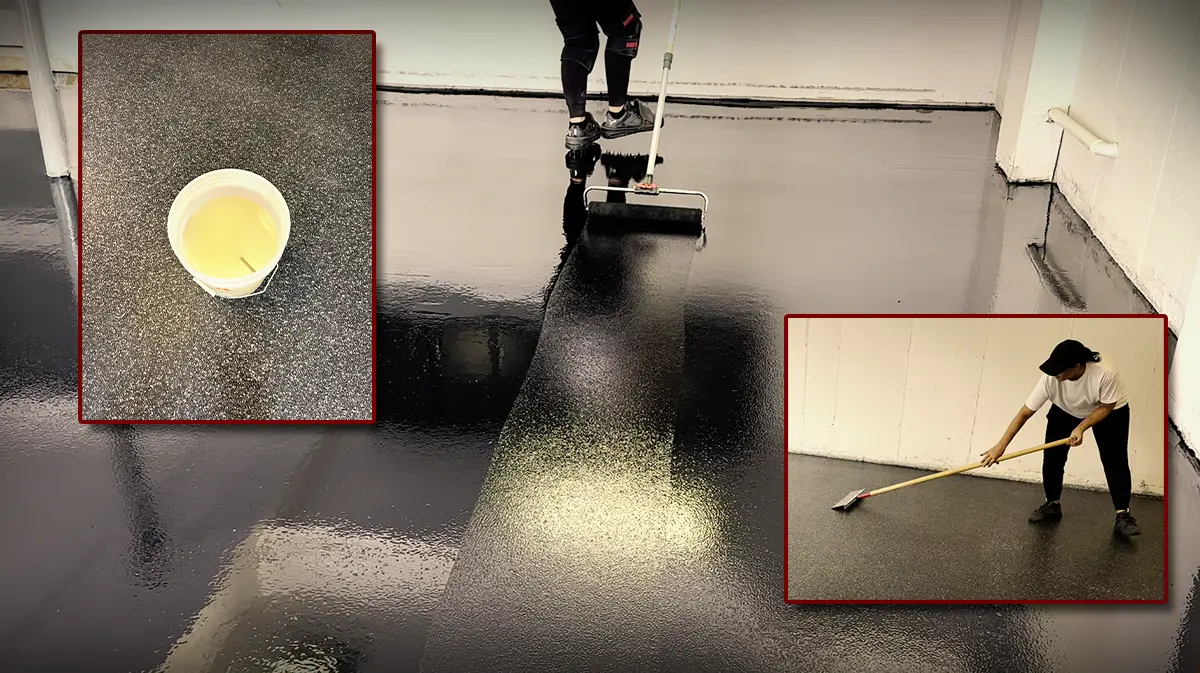

- Epoxy Coating: A slow-curing coating that consists of a resin (Part A) and hardener (Part B). When mixed, epoxies strongly bond with the concrete substrate, creating a thick, durable surface. However, epoxies tend to fade and amber when exposed to UV light. Hence, these coatings are excellent as garage floor primer coats, but must be covered with a full-flake broadcast or a color coat if exposed to UV.

- Polyaspartic Coating: A fast-curing coating relative to an epoxy. Excellent option as a top coat in Colorado Springs’ outdoor environments as these coatings provide extreme UV and chemical resistance. However, polyaspartics are poor direct-to-concrete primers, especially in the presence of concrete moisture (they tend to delaminate). Hence, they’re great for use as clear topcoats, but should be avoided as primer coats. As topcoats, the are ideal for busy areas needing fast turnaround.

- Polyurethane: Applied as a color or topcoat, polyurethane adds extra flexibility and UV resistance. However, polyurethanes can be odorous and do not protect against hot-tire transfer. As such, these coatings should not be used in garages, However, in Colorado Springs, where outdoor patios are exposed to sun and snow, this topcoat ensures long-term protection.

If you’ve heard the terms concrete paint, concrete floor paint, or garage floor paint — someone is either referencing literal paint that goes on concrete, and therefore not an actual flooring option, or they’re colloquially referring to epoxy flooring.

Epoxy Flooring World: Environmental Considerations

The local climate in Colorado Springs has specific environmental challenges that influence flooring choices, particularly when dealing with moisture, UV exposure, and temperature swings.

- Moisture Mitigation: Even though Colorado Springs is fairly dry, snow and ice in winter can cause moisture problems. Moisture mitigation prevents vapor from seeping up through concrete, preventing bubbles and peeling.

- UV Resistance: With higher altitude comes stronger UV rays. Polyaspartic and polyurethane coatings are both UV-resistant, ensuring that outdoor or sunny garage spaces don’t suffer from yellowing or damage.

Decorative & Functional Enhancements

In addition to durability, epoxy coatings can be enhanced with decorative elements, offering both style and practicality.

- Flake System: Decorative flakes are broadcast and become embedded in the epoxy coating. The flakes provide depth and texture and some slip resistance. Albeit, with Colorado’s snowy winters, floors can get wet and slippery, so added anti-skid aggregate (in the clear coat) is a must.

- Mica Flakes: For a more high-end look, natural mica stone flakes can be added to the flake blend. The result is a highly reflective finish (they literally sparkle in the light). Hence, mica enhances both the overall aesthetic of the floor and its durability.

Conclusion

In Colorado Springs, where floors face both extreme cold and high UV exposure, choosing the right coating is critical. Whether you’re looking for a tough epoxy flooring option, UV-resistant polyaspartic, or decorative enhancements, understanding these terms will help you make the best choice for your space.